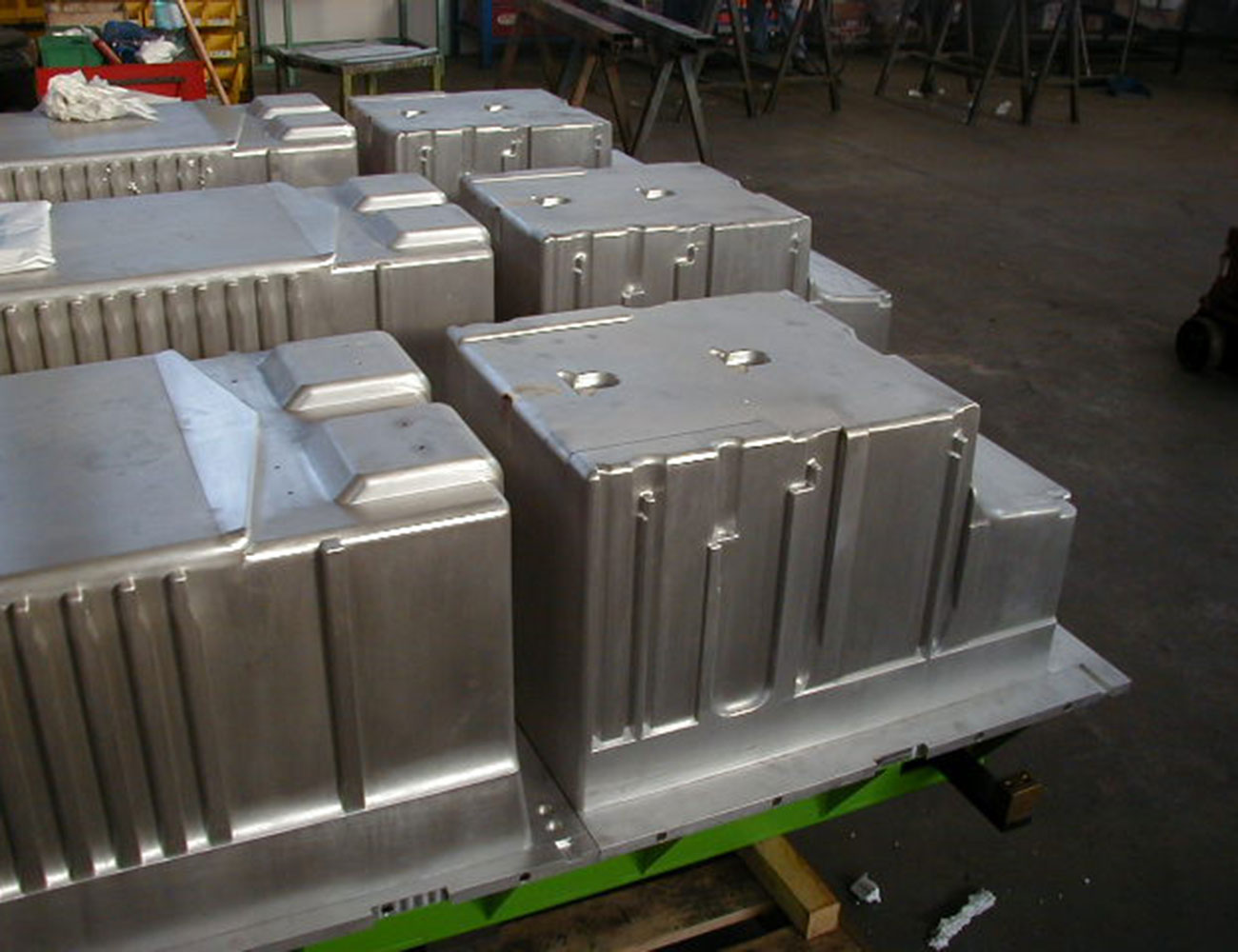

MOULDS FOR POLYURETHANE FOAMING

We design and manufacture moulds for polyurethane foaming for filling the cavities of cold rooms and doors, mainly for household appliances.

Our design department with its CAD / CAM equipment and our machining department with its modern CNC work stations enable us to produce foaming moulds tailored to the customer’s requests in the shortest time and with maximum precision.

Polyurethane Foaming

Polyurethane foaming is a process by which some chemical components like isocyanate and polyol are made to react within a specific machinery that mixes the components at high or low pressure.

Polyurethane foam is widely used as a thermal-acoustic insulator.

Thanks to its ability to expand it can be used for filling voids and cavities.

Our foaming moulds are inserted in foaming lines in the white household appliance sector to counteract the expansion of the polyurethane injected between the cabinet and / or door (external part of the appliance) and the thermoformed internal lining of cold rooms and / or doors.

Foaming Moulding Interfaces

The user interfaces for foaming moulds are used for installing our moulds on the machinery used by our customers.

Specifically for foaming, especially in the case of door foaming, these are frames for containing and adapting our moulds to dedicated foaming systems (Cannon, Krauss Maffei, QS, Hennecke, OMS).