We specialize in the production of moulds for thermoforming. In close collaboration with our customers, we provide the skills and experience of our technical team to create the best models and prototypes of moulds for thermoforming in the shortest possible time.

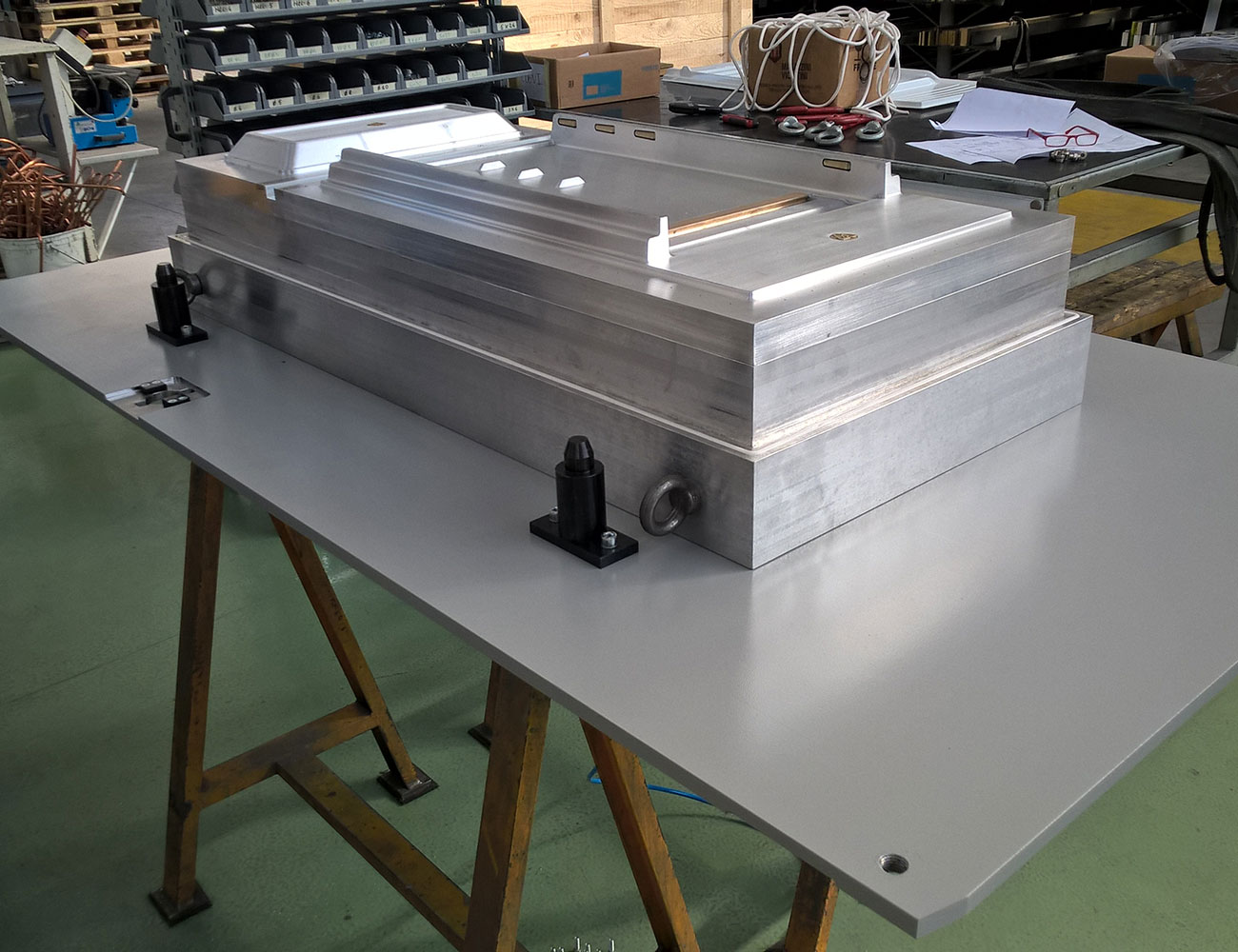

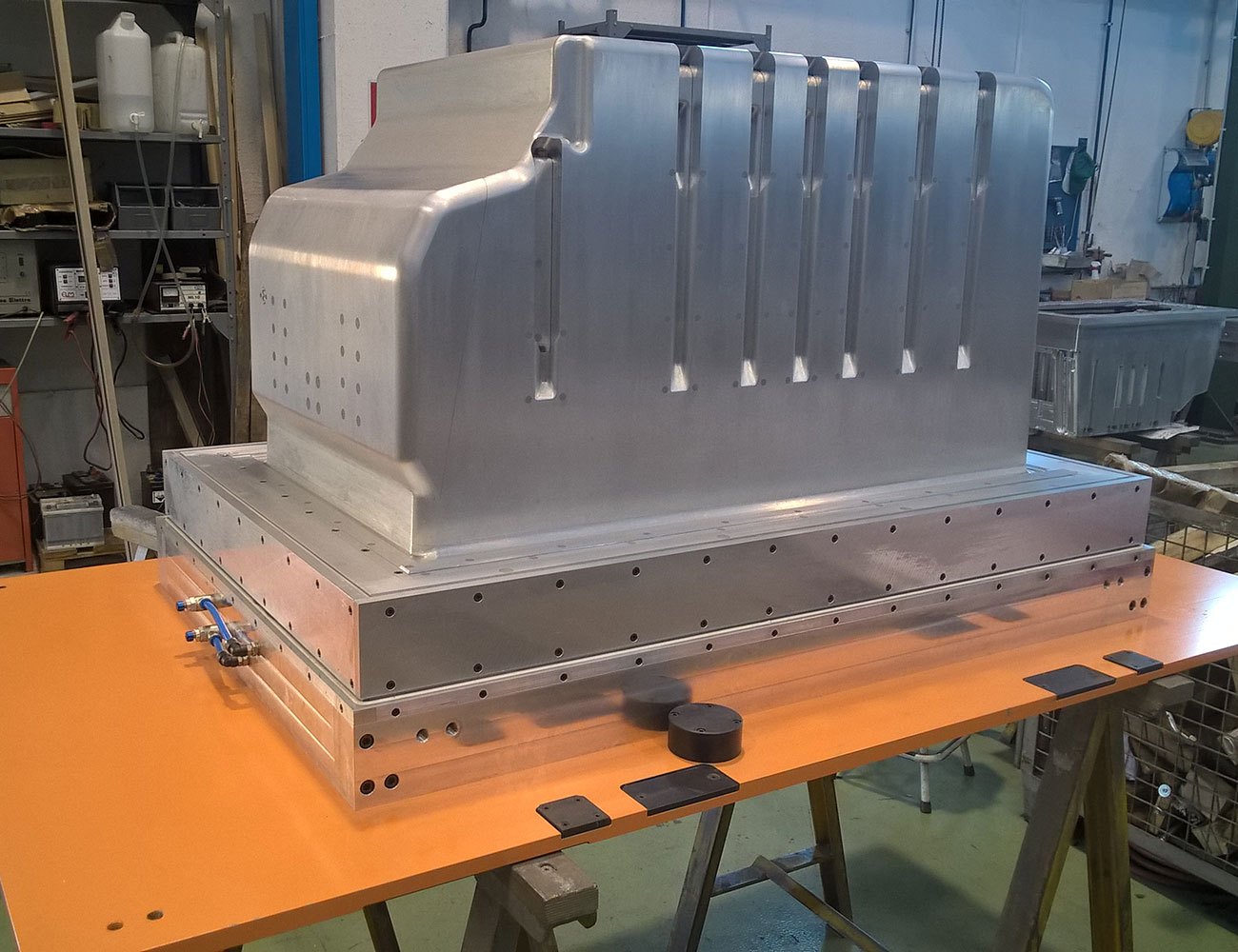

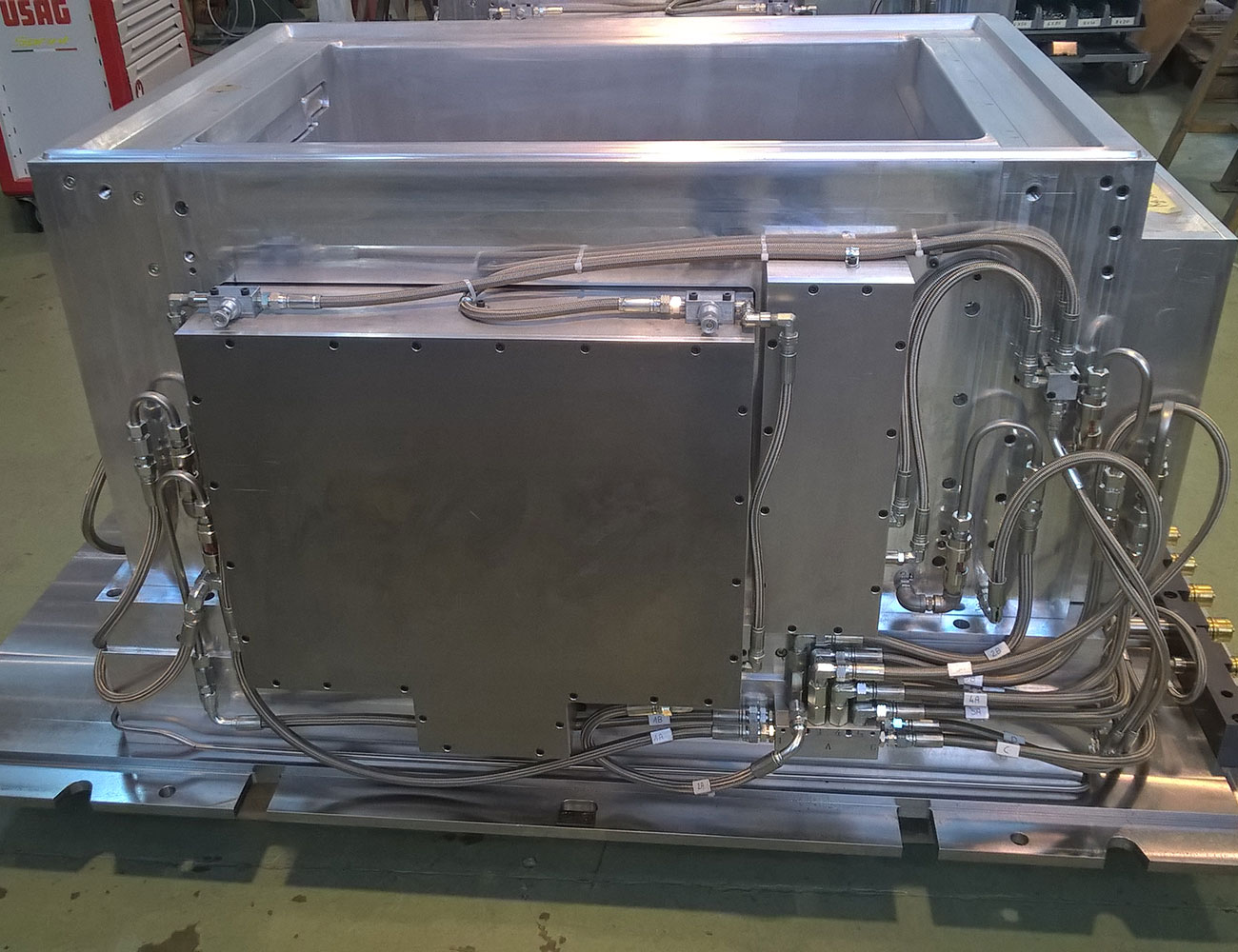

Moulds are manufactured with a milling process in CNC machining centres of the last generation. We use tested methods to guarantee the best result.

Thermoforming is a process through which a thermoplastic sheet is heated and deformed into the desired shape.

It basically consists of two steps: heating and forming.

Heating is usually accomplished by radiant electric heaters, located on one or both sides of the plastic sheet. The heating cycle duration must be long enough to sufficiently soften the sheet.

Our thermoforming moulds are suitable for vacuum thermoforming and vacuum / pressure thermoforming, both involved in the industry:

- In vacuum thermoforming, negative pressure (vacuum) is used to adhere the preheated sheet into the cavity of a mould, whereas

- in vacuum / pressure thermoforming, in addition to vacuum, pressure (1 to 3 bar) is also used during the phase of forming the sheet into the mould cavity.

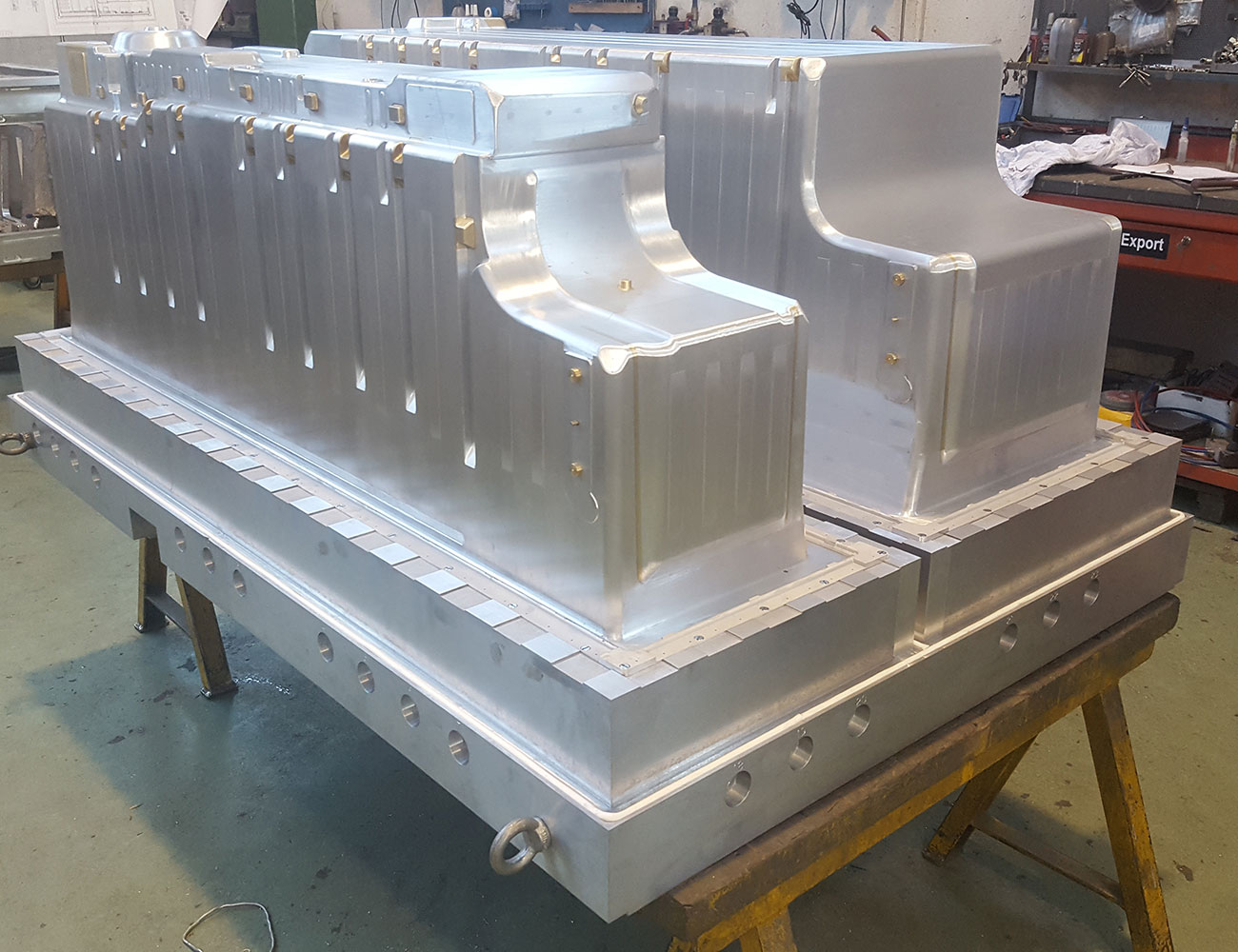

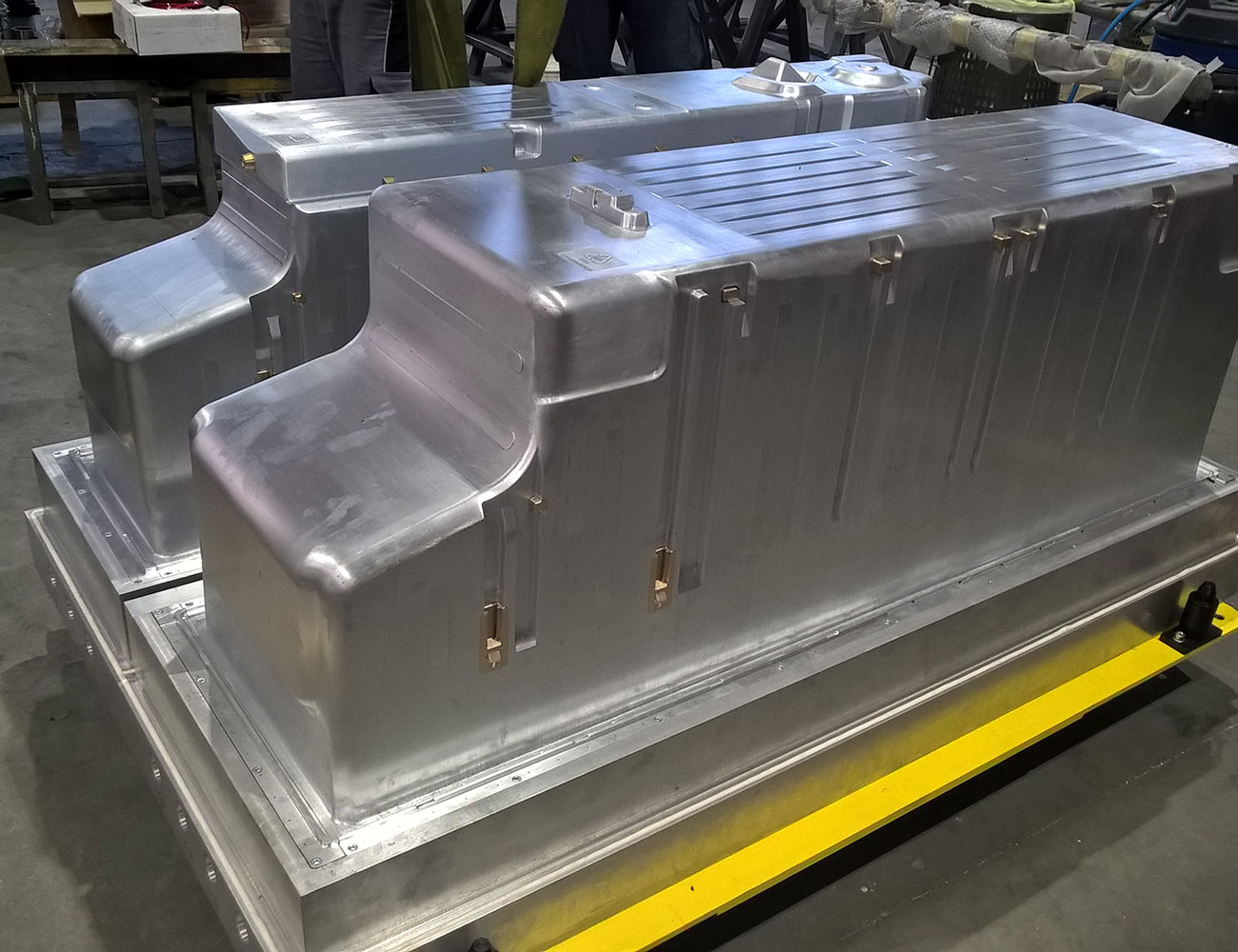

Our moulds for the thermoforming of refrigerator doors and cold rooms are used to deform the plastic sheet that will take the shape of the internal part (internal lining) of cold rooms and freezers, both on the mobile side and on the door side, used in the white household appliance sector.

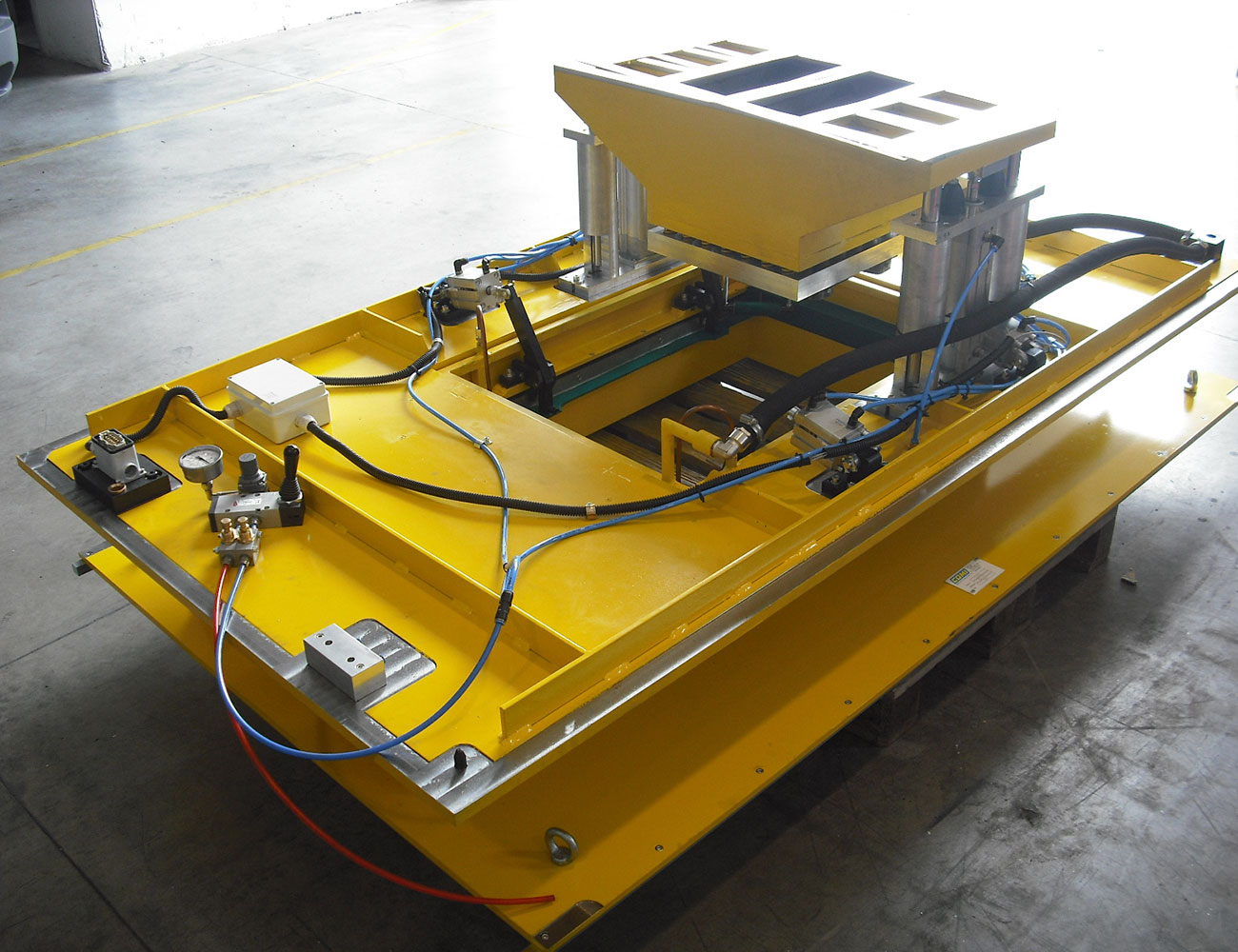

Foaming Moulding Interfaces

The user interfaces for foaming moulds are used for installing our moulds on the machinery used by our customers.

Thanks to the adapter interface, the thermoforming mould can be installed directly on the customer’s machine.

Specifically for foaming, these are frames for containing and adapting our moulds to dedicated foaming systems (Cannon, Krauss Maffei, QS, Hennecke, OMS).

Accessories for the processing of thermoformed components

Used after the forming process, they include, inter alia, blanking tables and specific equipment for punching slots and / or various figures, as required.

Taylor-made accessories are also delivered, upon request.